-

Products

Embedded Computing

- AIoT Software, Distribution & Services

- Application Focus Embedded Solutions

- Arm-Based Computing Platforms

- Computer On Modules

- Digital Signage Players

- Edge AI & Intelligence Solutions

- Embedded PCs

- Embedded Single Board Computers

- Fanless Embedded Computers

- Gaming Platform Solutions

- Industrial Display Systems

- Industrial Flash & Memory Solutions

- Industrial Motherboards

- Industrial Wireless Solutions

- Wireless ePaper Display Solutions

Applied Computing (Design & Manufacturing Service)

Industrial Automation & I/O

- Automation Controllers & I/O

- Certified Solutions

- Class I, Division 2 Solution

- Data Acquisition (DAQ)

- Embedded Automation Computers

- Gateways & Remote Terminal Units (RTUs)

- Human Machine Interfaces

- Motion Control

- Panel PC

- Power & Energy

- Remote I/O

- WebAccess Software & Edge SRP

- Wireless I/O & Sensors

Intelligent Connectivity

Intelligent Systems

- Box IPC

- CPCI & VPX

- Industrial Computer Peripherals

- Industrial GPU Solutions

- Industrial Motherboards & Slot SBC

- Intelligent Transportation Systems

- Modular IPC

- Rackmount IPC

Cloud, Networking & Servers

- Industrial, Telecom and Cloud Servers

- Network Interface & Acceleration Cards

- Network Security Appliances

- SD-WAN & uCPE Platforms

- WISE-STACK Private Cloud

Computer Vision & Video Solution

-

Solutions

Solutions

- Services

-

Partners

Business Alliance Partner

- Support

- Corporate

- Contact

Visit the Advantech Global website, or choose your country or region below.

Africa & Middle East

MyAdvantech Registration

Start Your Digital Transformation

Manufacturing in the past has focused on lean and just-in-time production processes, emphasizing cost reduction, waste elimination, and increased efficiency of the entire organization through customer demand-pulling processes. Nowadays, digital technology provides fundamental value that presents commercial value through the immediacy and accuracy of information — driving rapid responses and decision-making. Many manufacturers who have progressed through Industry 2.0 (automation) and Industry 3.0 (informatization) are now preparing to move toward Industry 4.0 (intelligentization).

Driving Perfect Strategies for Three Core Trends of Transformation

Sustainability & Work Safety

- Improve energy efficiency

- Energy base line & performance indicator monitoring

- Boost energy savings

Production Reliability

- IoT data acquisition and recording

- Improve failure prevention and cost control

- Equipment workflow optimization

Data-Driven Decisions & Optimization

- Increased productivity

- Implement agile-manufacturing

- Cross-domain solution (I.App) integration

Focused Industry Segments

Food & Beverage

Metal Processing

Footwear & Textile

Semiconductor

Automotive & EV

PCB

Pulp & Paper

Electrical Machinery

Food & Beverage

Challenges

- Complex process

- The failure and time wastes in the manufacturing process

- Food safety and quality control

- Energy-intensive process and environmental challenges

How We Solve

- Optimized production flexibility and efficiency

- IoT connection for easier data collection and equipment monitoring

- Improved quality control with AI technology and food traceability

- Protects the environment and maximizes energy efficiency

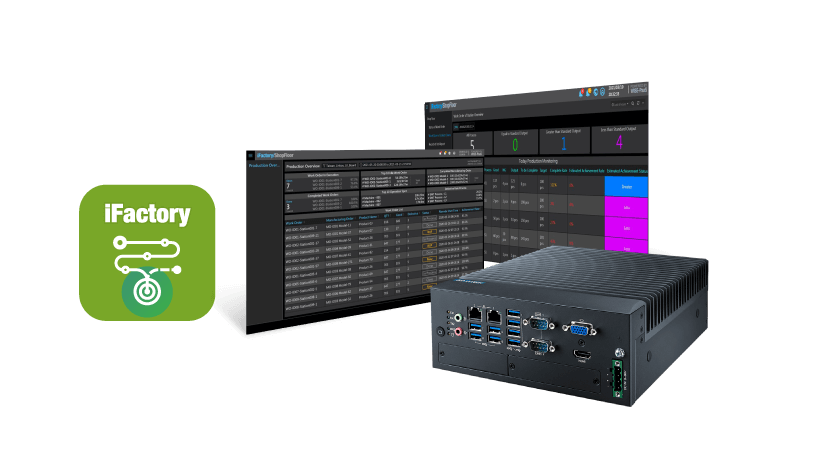

Accelerate Growth with WISE-iFactory

To confront future challenges, Advantech developed iFactory solutions which combine leading edge computing hardware and easy-to-use software to offer Low-code platforms that accelerate digital transformation and Industry 4.0. To develop complete industrial solutions that enable manufactures to easily move forward, Advantech provides the WISE-IoT platform: iFactory EHS, iFactory EAM, and iFactory TPM that allow DFSP (Domain-Focused Solution Partners) easy access to all featured modules. This helps them easily collaborate with Advantech to offer rich services and tools to their focused vertical industry customers.

Real Cases

Related Insights

Smart Manufacturing Ecosystem

Global Industry 4.0 Success Stories

Reshaping Manufacturing Business Operations with Industrial IoT

Featured Products

Edge Solution Ready Packages

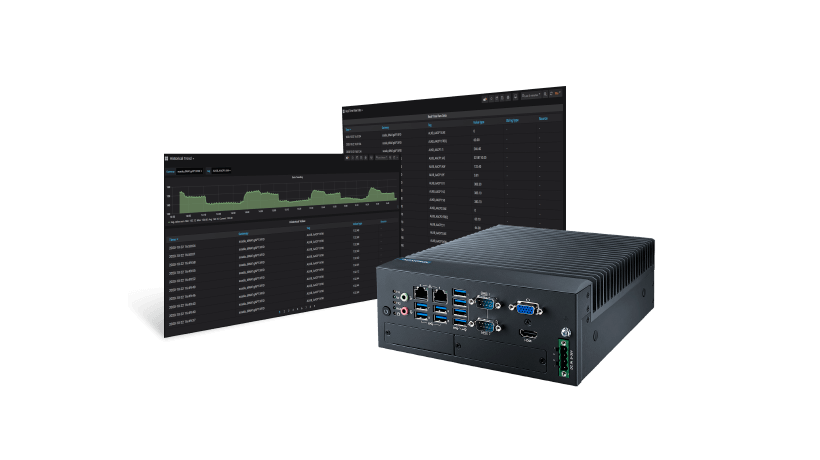

Real-time monitoring and management production equipment, process control, and energy consumption in industrial plants.

iFactory Real-time Monitoring

(RTM)

(RTM)

Real-time machine availability management for maximizing operational excellence.

Overall Equipment Effectiveness Solution (OEE)

Centralized monitoring and data management for energy efficiency optimization.

Facility Management and Sustainability Solution (FMS)

An easy-to-use tool to speed up the visualization of all machine status and health conditions

Equipment Maintenance

Solution

Solution

A set of manufacturing management systems and tools for production tracking, scheduling, and status reporting.

Shop Floor - Production Schedule Management Solution

An important management tool in lean manufacturing which can notify relevant personnel immediately when the production process is interrupted.

Andon - Abnormal Event Management Solution

Provides digital production SOP with a management system to achieve paper savings, reduce maintenance and management time, and enhance the convenience of on-site operators.

eManual - Digital SOP Management Solution

The iFactory Edge Solution Ready Packages focuses on prioritized markets with higher automation maturity—those with the capability to incorporate smart factory and Industry 4.0 technologies.

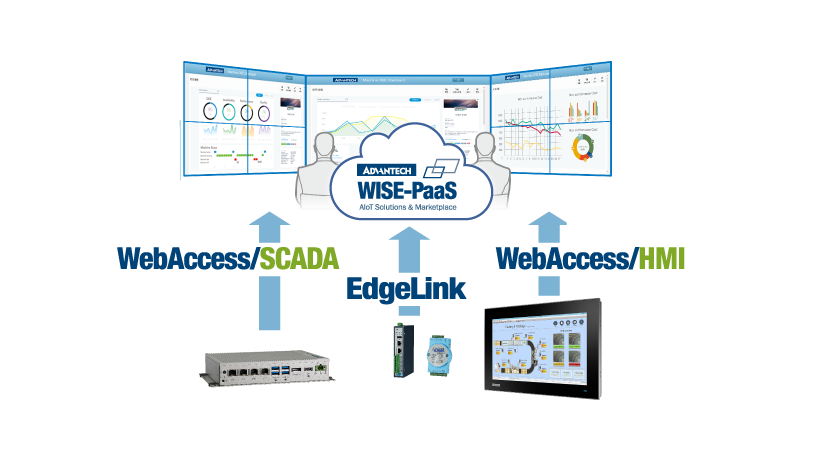

WebAccess Software & Solution Ready Packages

Data Connectivity & Collection

The intelligent systems, MIC, IPC and AIIS Series, have various form factors and are designed with high performance CPU and GPU computing, multiple I/O, and expandable functions.

Intelligent Systems

The UNO series embedded automation box PCs are ideal for edge computing and bridge the gap between IT and OT. This series serves as flexible IoT gateways in different sizes and various mountings.

Embedded Automation Computers

The ADAM-6700, ECU series, and remote terminal units (RTUs, ADAM-3600) with WISEEdgeLink software can securely convert different protocols and transmit data to the cloud and/or other third-party systems.

IIoT Gateways and RTUs

The ADAM series remote I/O modules have empowered industry for over 30 years. This category includes Modbus RS-485, Ethernet to OPC UA Ethernet I/O modules with IT/OT protocols for remote facility monitoring and process control.

Remote & Wireless I/O and Sensors

A complete range of PCI, PCIE cards, USB modules, modular DAQ systems, and DAQ-embedded computers for domain-focused test and measurement and predictive maintenance applications.

High Speed DAQ

Edge Analytics

Advanced AI technology, in combination with IoT technology, is redefining entire industries using smart applications. Advantech has collaborated with NVIDIA to deliver AI products at the edge for AI inference and training.

Edge AI Systems

Peripheral Devices

Compact EtherCAT Controller and Slice I/O are designed with the smallest programmable automation controller (PAC) in the high computing processor, modular I/O, and a PCIe communication interface.

Edge Controllers & I/O Systems

Advantech's industrial Panel PC product portfolio include customizable and all-in-one touchscreen pc series with multiple industrial touch panel sizes and rich I/O expansion to meet any HMI service.

Industrial Panel PCs

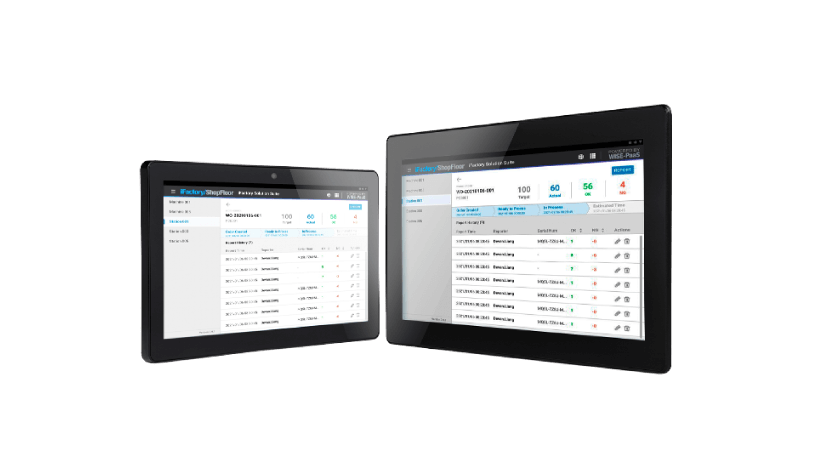

AIM industrial-grade tablets, available in 8” and 10” sizes, provide real-time data access, enabling field workers to make informed decisions on the industrial spot.

Industrial Tablets

The ULI Series offers serial / USB communication products to help optimize your legacy serial assets by connecting them to the IoT world. The serial cards feature RS-232 / CAN bus cards and communication boards that need only one PCI or ISA slot to provide independent serial channels.

Serial & USB Communications